The last few weekends I have been fortunate. My wife has demanded that I finish some projects around the house. Normally, I would probably whine and complain about having to finish projects because those projects are usually things like organizing the filing cabinet, sharpening crayons, dusting under the bed, and arranging the pantry into alphabetical order. These projects, however, are much more fun. Finishing the shed, is the unfinished job (one of hundreds) I have been focusing on lately.

|

| Almost Finished... |

In addition to shingling the roof (boring asphalt on one side and metal panels on the other) I decided to shingle the walls, with cedar shingles. One note I'd like to make up front is that this is my first experience with installing cedar shingles. I did receive some advice from someone who used to install these for a living, and I did some research on my own. After working with them for a few days, I'd say that a project this size is perfect for someone looking to learn a little about the basics of working with these. I decided to go with cedar shingles as opposed to shakes as that is what my local hardware store had in stock. Just a quick mention (as it was explained to me in rather passionate detail) is that shingles are typically milled/sawn on both sides, while shakes are split (typically by hand) on one or both faces. As a result, shingles are more uniform in appearance than true shakes. I would also recommend taking my friends advice and be very wary about purchasing cedar shingles from a big box hardware store. I got a mix of 3 and 4s from my local big box and quickly realized that they were one step away from mulch. I realize that 3 and 4s are the bottom of the bunch, but these were worse than I expected. These are pretty much thrown together into ungraded bundles and shipped out the door to make a buck. Fortunately, due to some rather aggressive roof overhangs these shingles won't actually get too much weather. If I were doing a larger project, a roof, or something that required a more consistent appearance, I would likely order higher grade shingles or shakes from a reputable mill/producer or dealer in hopes that I'd get a more consistent and better quality product.

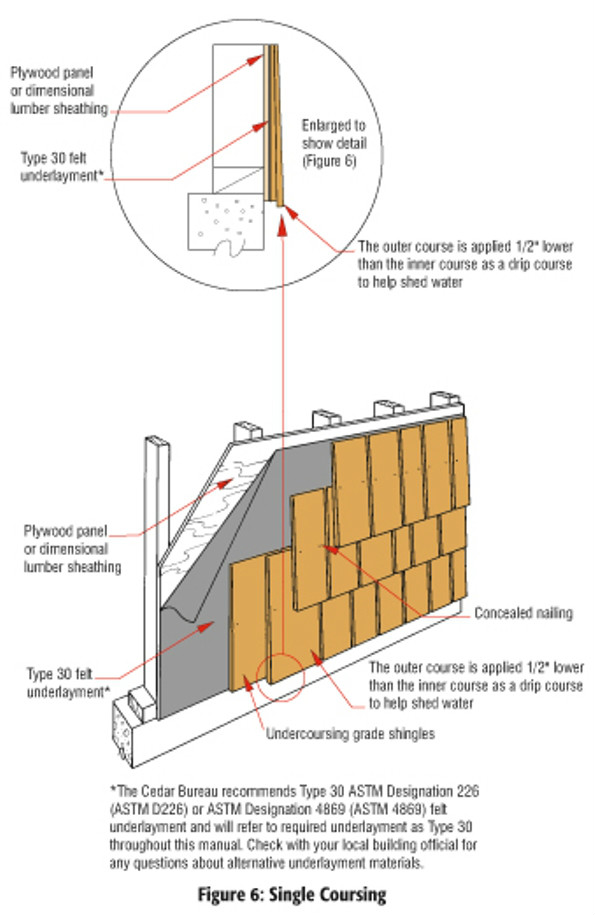

That being said this was a good learning experience (although I am not quite finished...). I split all the shingles to width (when needed) with a carpenters hatchet that I refurbished last year, and more complicated cuts included the use of a handsaw and a chisel. Most of the shingles had decently straight grain so they split fairly easily. I didn't need to plug in my miter saw at all, which let me work much more quietly and efficiently (although I did use a pneumatic roofing nailer to install the shingles). Being able to cut/split everything without having to walk all over the place was nice. As with all construction techniques, there are a million and one ways to install cedar shingles. The thing I like about shingled siding is that depending on the installation technique the shingles can look perfectly trimmed and modern or they can be more rustic and imperfect. I intentionally installed these in a slightly random fashion to keep some visual interest. I followed along each row with a short level to make sure I wasn't getting too far out, but everything else, with exception of the first course, was just installed via a well calibrated eyeball (I winged it). I did the first course and undercourse like the diagram below:

|

| The North Side |

I opted for site-made cedar "j-channel" (not installed yet) which will just be two staggered pieces of cedar trim on the corners of the shed to keep weather off of the very edges of the corners. Another technique that I think would have worked well is to lace the corners, which looks nice.

Other techniques:

|

| Illustration from http://www.cedarbureau.org |

Maybe for the next shed I'll split my own shakes like this guy...

Give me new videos! Oh question if I were to make a small bench and im super limited to resources and moolah. Should I make it out of pine two by fours?

ReplyDeleteVideos are coming...I promise... Really, anything can make a usable bench, pine two by fours, plywood, scrap lumber. anything...except maybe concrete. If you have access to pine two by fours, just try your best to pick through and get the clearest, straightest ones you can (knots and holes will complicate things). A 2x4 or 2x6 top can be laminated up with some glue and screws and you can make the legs out of the same. A nice flat top and lots of weight will help if you are using hand tools on the bench. You can add weight by putting a shelf along the bottom of the legs and sitting cinder blocks or sand bags on the shelf. The most important aspect of the bench is that it works for you. Plus, the nice thing about a beater bench is that you aren't afraid to modify it, adjust it and use the hell out of the top.

ReplyDeleteThanks! ohh also i'm planning on having my career spin around making hand made furniture. If you don't mind me asking if i were to buy my first full sized hand plane what kind? Smoother, jack, or jointer cause I want to invest in one i can get the most out of.

ReplyDeleteAwesome news about your career! If I had to get rid of all my planes but one, first I'd cry like a two year old girl who dropped her ice cream in the sand, and then I'd set aside my Lie Nielsen #62 low angle jack plane. I wrote a quick post about it here: http://www.polthaus.com/2011/10/universal-soldierno-need-for-dolph-and.html This plane is useful for a large number of different tasks, it's sort of the Swiss Army Knife of the plane world. I'd recommend getting a couple different blades for it (offered by Lie Nielsen), as those are what really make it a multi-tool. The next thing I'd recommend is a good arsenal of clamps, vises and anything that looks like a decent work-holding device.

DeleteThanks! I'm thinking about going with Veritas low angle jack, because I can't get the lie Nielsen jack without internation mailing. Living in canada has its downfalls.

ReplyDeleteIncredible blog. Love it. Keep sharing more blog in future on this topic.

ReplyDeleteSarasota Roofing Contractors

Thank you for this valuable information. Get your business to the next level in simple step. Send Flowers To USA

ReplyDelete